Mobile racking is a specialist high-density system often designed for long-term storage of pallets or other heavy goods. It provides maximum storage capacity in minimal square foot requirements. by eliminating aisles and compacting ranges, it can store products in half of the space as conventional shelving.The racking runs are mounted on mobile bases, which run on rails up and down the storage area. The bases are electronically driven and are normally kept closed leaving one aisle for access.

Mobile racking is a specialist high-density system often designed for long-term storage of pallets or other heavy goods. It provides maximum storage capacity in minimal square foot requirements. by eliminating aisles and compacting ranges, it can store products in half of the space as conventional shelving.The racking runs are mounted on mobile bases, which run on rails up and down the storage area. The bases are electronically driven and are normally kept closed leaving one aisle for access.

Maximum use of floor space as only one operating aisle required

- Good occupancy rates

- 100% individual pallet access

- Particularly suitable for temperature controlled stores

- Non specialist handling equipment

- Flexible in height/width of load unit

- Random position allocation

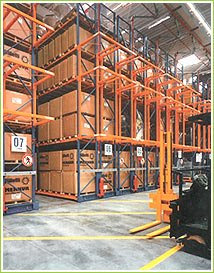

By allowing fork trucks to operate in aisle up to half the width required in conventional adjustable beam pallet racking, Narrow Aisle racking makes excellent use of floor space and maximises the height at which goods can be stacked. The pallets are accessed via specialist trucks, which are guided in the very narrow aisles by either low or high profile floor mounted rails or electronic wire guidance in the floor. As storage locations can be only accessed using specialized equipment, the security of valuable products is improved. Besides that, the sophisticated handling equipment improves the safety of load handling within the racking system.

By allowing fork trucks to operate in aisle up to half the width required in conventional adjustable beam pallet racking, Narrow Aisle racking makes excellent use of floor space and maximises the height at which goods can be stacked. The pallets are accessed via specialist trucks, which are guided in the very narrow aisles by either low or high profile floor mounted rails or electronic wire guidance in the floor. As storage locations can be only accessed using specialized equipment, the security of valuable products is improved. Besides that, the sophisticated handling equipment improves the safety of load handling within the racking system.

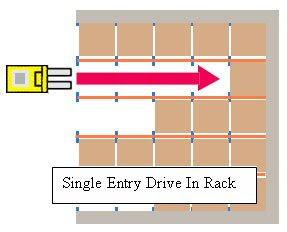

Drive-In racking is very ideal for high-density storage. It is frequently used in facilities with a low number of product lines. Pallets are stored in a block system with two blocks generally served by one operating aisle. It provides high-density and better cubic utilization storage. This is due to fewer aisles required which allows 75% more pallets stored in the same space.

Drive-In racking is very ideal for high-density storage. It is frequently used in facilities with a low number of product lines. Pallets are stored in a block system with two blocks generally served by one operating aisle. It provides high-density and better cubic utilization storage. This is due to fewer aisles required which allows 75% more pallets stored in the same space.

Single Entry Racks - lift trucks can enter the rack from only one side.

Single Entry Racks - lift trucks can enter the rack from only one side.